Discover

WEARMAX® Colour System

The fast, resilient solution for versatile applications

Our color system is perfectly suitable,

to give a completely new look to heavily used resilient floor coverings.

WEARMAX® Colour system can be used on almost any substrate such as plastic/PVC, linoleum, synthetic rubber flooring and rubber as well as wood and parquet flooring due to its superior technical properties.

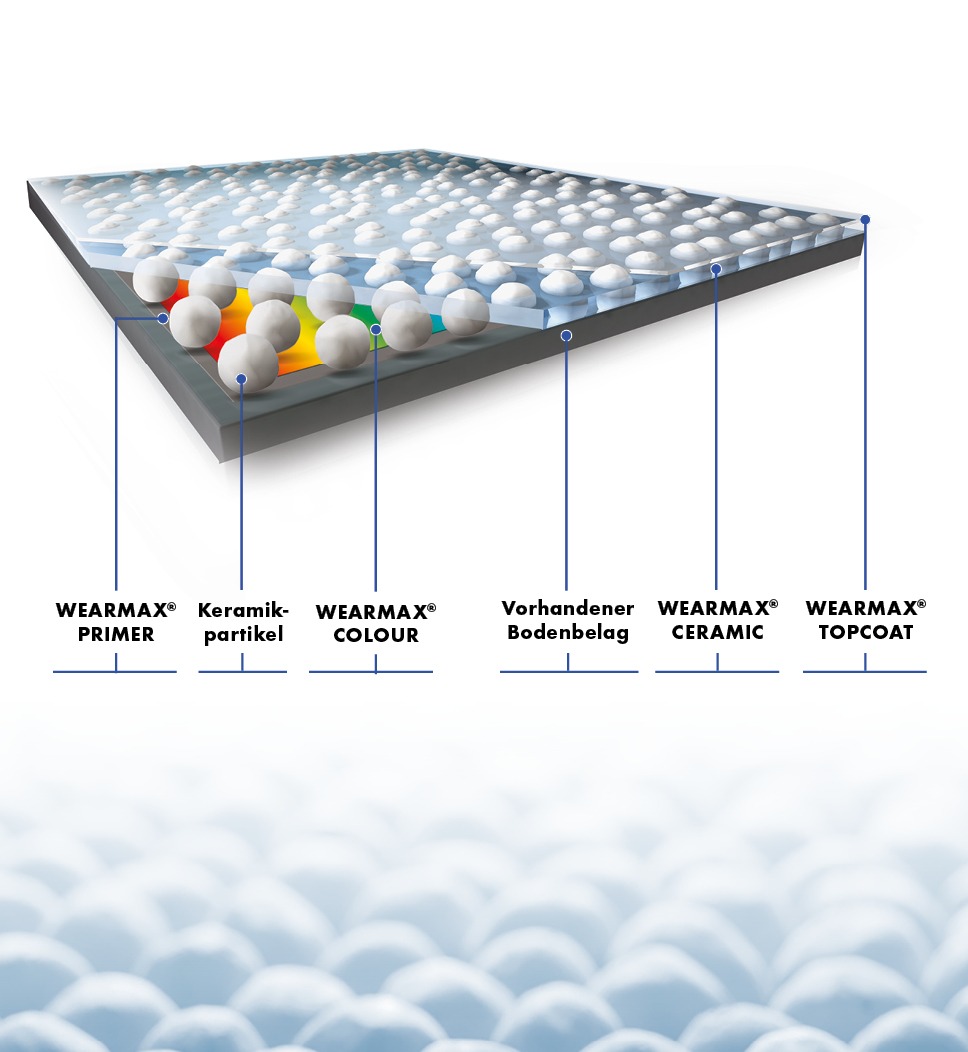

The unique technology of WEARMAX® High-Performance Ceramic Coating anchors 120 million ceramic particles per square meter suspended on the surface in a flexible coating system.

During processing, a wafer-thin ceramic layer, invisible to the naked eye, is applied. It protects the floor highly effectively against wear, abrasion and soiling and improves slip resistance.

Take advantage of the following benefits:

– Largely resistant to disinfectants (ask for our positive list of disinfectants).

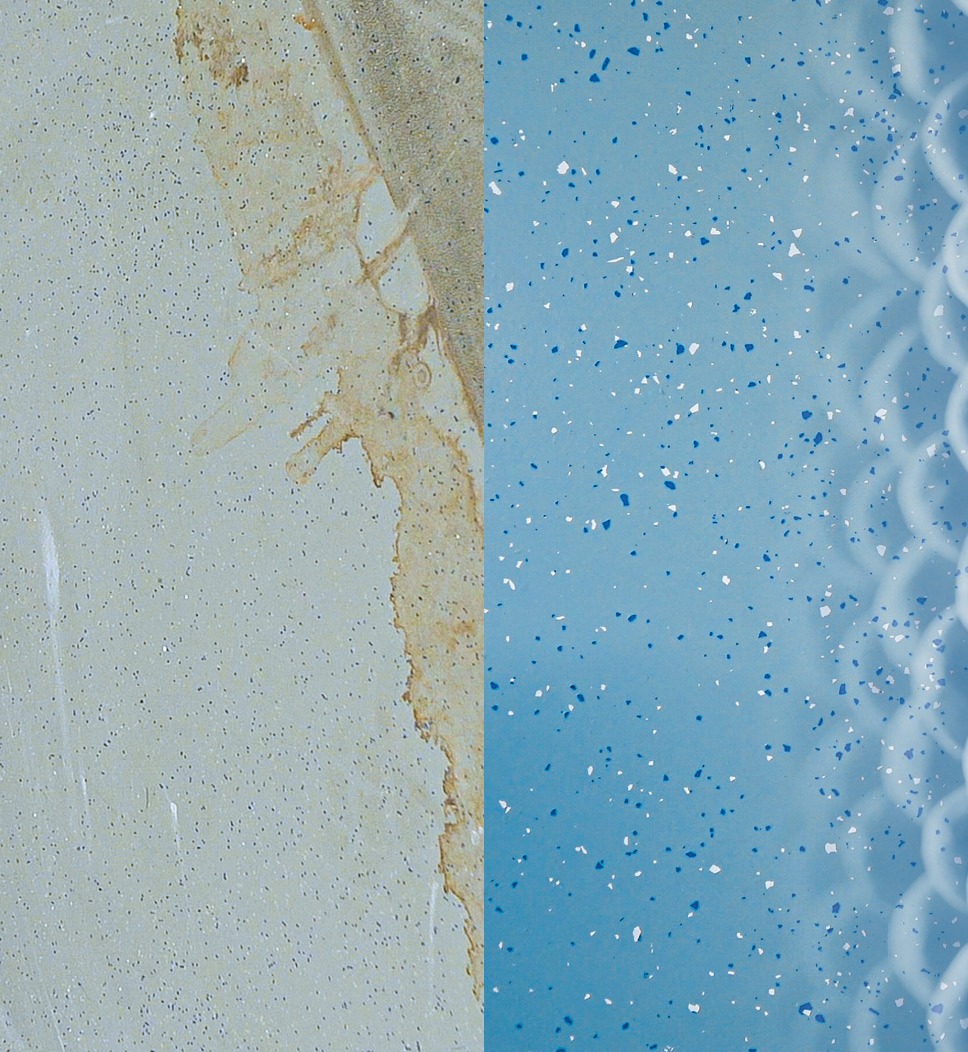

– Significant extension of the service life of existing, heavily worn floors

– Long-term protection against wear, abrasion and signs of use

– Increased scratch resistance in the final surface

– Positive effects on the slip resistance class

– Low resoiling

– Economical and environmentally friendly

Three or four layers in one. Quickly applicable and economical

Colour floor system

“Our Colour System (3 or 4 in 1 product): ideal for renovating heavily worn floors. When the original appearance is already badly damaged, but basically still worthy of renovation.”

The Colour System consists of three layers: the primer (optional), the color layer, the ceramic layer and the top layer.

Here we show you the main steps of the processing. Watch the video on our Youtube channel to follow in detail the whole process of application on an old PVC floor.

The first (optional) layer

The system is basically applied in 3 work steps (if necessary – recommended for open-pored, highly absorbent floors – the floor covering should be additionally pre-treated with WEARMAX® Universal Primer).

The paint layer

Machine-mixed with hardener and water, WEARMAX® Colour is applied by roller three to six hours* after application of the primer. Choose from a wide range of RAL colors!

* … better to wait overnight for wooden floors!

The ceramic layer

Machine-mixed with hardener and water, WEARMAX® Ceramic is applied twelve hours (or overnight) after WEARMAX® Colour has been applied using a roller (hydro-flow roller) and T-bar (sponge roller). Always empty only as much ceramic liquid onto the floor as you can process in the shortest possible time. Apply WEARMAX® Ceramic in one step. Then allow the treated area to dry for at least 3 hours.

The top layer

Machine-mixed with hardener, WEARMAX® Top Coat is applied by roller three hours after WEARMAX® Ceramic is applied. The floor can thus be used to a limited extent after eight hours and completely after 72 hours. The final chemical hardness is reached after eight to ten days.

Here's how

In our video you can see all processing steps of WEARMAX® Colour System. The processing stages depend on the condition of the original substrate, so they vary from project to project.

Space Planner

Create Your Floor

We support your design requirements! The floor configurator “Create your Floor” is the perfect tool for architects, planners, floor profis or building contractors. This digital visualization tool shows you how different floors look in your room!

NOW TO THE FLOOR CONFIGURATOR

CALCULATE THE EXPENSES FOR YOUR CONSTRUCTION SITE

with our cost calculator

Based on our best practice projects, we have developed a simple cost calculator. You can use the calculator to get an overview of all the costs you may incur on your own project.

Since each construction site has different requirements, this calculator is for guidance only. We cannot guarantee that your actual cost will always be the approximate result.

Cost calculator

Lino, PVC and rubber floor