Discover

WEARMAX® Transparent System

The fast, resilient solution for versatile applications

Our Transparent System: ideal for renovating heavily worn floors.

Restores the original appearance of wood or resilient flooring.

WEARMAX® Transparent can be used on a wide range of substrates such as plastic/PVC, linoleum, synthetic rubber flooring, rubber as well as wood and parquet flooring. Thanks to its outstanding technical properties, it proves to be extremely versatile.

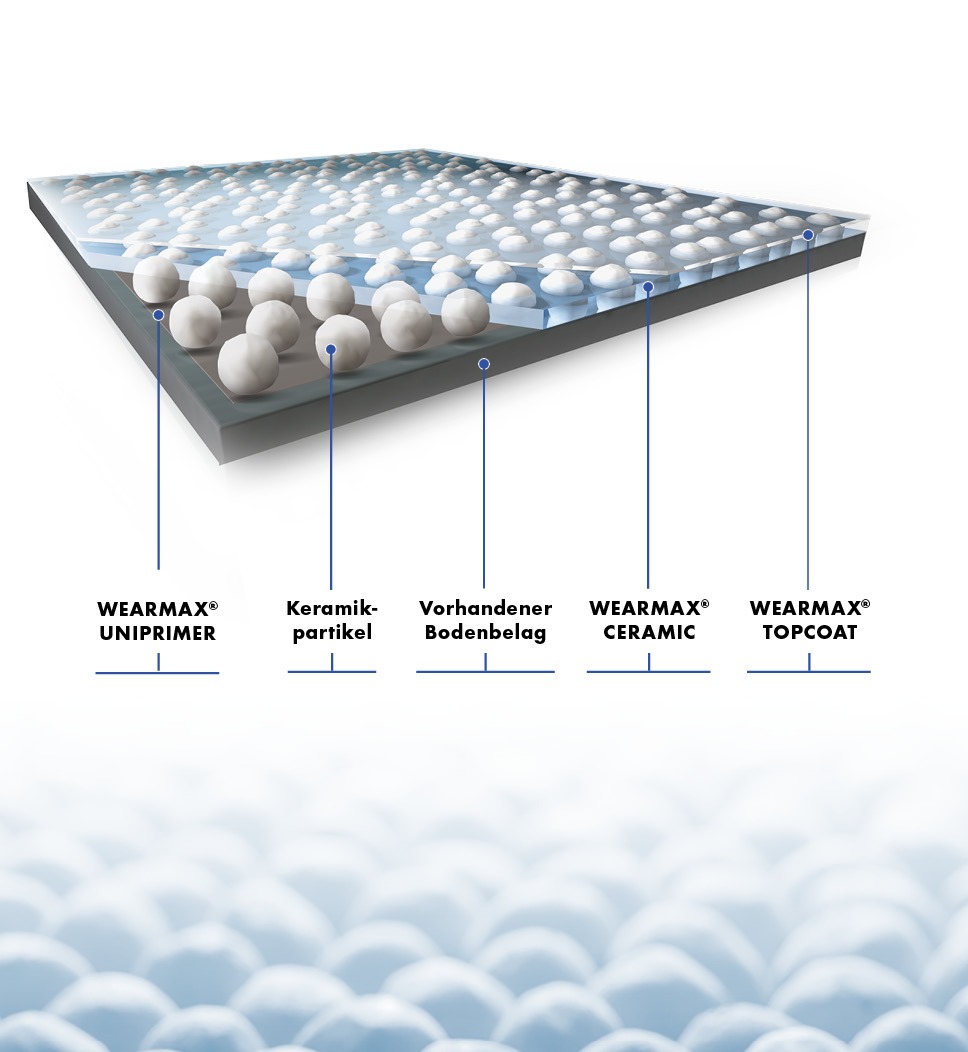

The unique technology of WEARMAX® High-Performance Ceramic Coating ensures that 120 million ceramic particles per square meter are suspended on the surface in a flexible coating system. During processing, a wafer-thin ceramic layer is applied that is invisible to the naked eye. This layer provides extremely effective protection against signs of use, abrasion and dirt, and also improves the slip resistance of the floor.

Take advantage of the following benefits:

– Largely resistant to disinfectants (ask for our positive list of disinfectants).

– Significant extension of the service life of existing, heavily worn floors

– Long-term protection against wear, abrasion and signs of use

– Increased scratch resistance in the final surface

– Positive effects on the slip resistance class

– Low resoiling

– Economical and environmentally friendly

Three layers in one. Quickly applicable and economical

Transparent floor system

“Our Transparent System (3 in 1 product): ideal for renovating heavily worn floors. Restores the original appearance of wood or resilient flooring.”

The Transparent System consists of three layers: the primer, the ceramic layer and the top layer.

Here we show you the main steps of the processing. Watch the video on our YouTube channel to see in detail the entire process of application on a 40 year old linoleum floor.

The first layer

WEARMAX® Universal Primer is applied by roller on clean, sanded and neutralized floor.

The second layer

Machine-mixed with hardener and water, WEARMAX® Ceramic is applied with roller and T-bar three hours after primer application.

The last layer

Mixed with hardener by machine, WEARMAX® Top Coat is applied by roller (hydro-flow roller) after the approx. 3-hour drying time of the previous coat has elapsed. The floor can thus be used to a limited extent after eight hours and completely after 72 hours. The final chemical hardness is reached after eight to ten days.

Here's how

In our video you can see all processing steps of WEARMAX® Transparent System. The processing stages depend on the condition of the original substrate, so they vary from project to project.

SUCCESS STORIES OF OUR CUSTOMERS

Case study: Premiere League Club

BACKGROUND

Sports and events stadiums are iconic properties across the UK and are home to some of the Premier League’s biggest clubs.

With thousands of fans and staff in attendance on game days and stadium tours becoming increasingly popular, these venues are often subject to heavy foot and vehicle traffic.

Many stadiums opt for rubber flooring – a durable, joint-friendly flooring that is easy to install and well-suited for large venues. Despite its durability, the sheer volume and nature of traffic can cause wear and abrasion to the floor surface over time, making it gradually more difficult to maintain and protect.

In addition, the inadequate entrance mats at some stadiums are unable to remove excess moisture and debris carried in by shoes and trolleys, further stressing rubber walkways.

CONSULTATION

Our B2B partner, Traffik, was delighted to be asked for advice by LSS, which is responsible for maintenance work on behalf of one of the biggest Premier League clubs.

LSS provides support services to the sports and leisure market, delivering operational excellence at each of its client sites, including soccer stadiums.

In this particular case, LSS and the client were looking for a floor sealant solution that would protect the existing rubber floor, enhance the aesthetic appearance of the surface, as well as exceed a value of 36 (pendulum value BS7976) according to British Standards for slip resistance.

What was needed was a ground seal that could withstand the demands of traffic, while also being suitable for mechanical and manual cleaning and having a winning appearance throughout.

The new flooring should allow for easier cleaning and reduce the amount of ongoing maintenance required for the floor.

Due to the scale and popularity of the venue, it was also important to be able to ensure a quick and easy relocation with minimal disruption.

SOLUTION

After several consultations with the customer, Traffik recommended WEARMAX® Transparent System as the optimal solution for the rubber floor.

The superior abrasion resistance offered by WEARMAX® creates a much more durable surface than other floor sealers and is well suited for sports and event venues.

WEARMAX® is also very quick and easy to apply, which met the requirement for rapid turnaround.

WEARMAX® is a floor sealant that anchors ceramic particles suspended on the surface. After drying out, the existing floor surface has been given a ceramic coating, so to speak – unlike other sealers where ceramics are used to cure the core of the sealer.

Core cleaning costs are significantly reduced (by up to 50%), as WEARMAX® can also be cleaned with water only. No stripping, sealing, buffing, polishing, burnishing or maintenance pads are required. This reduces labor, supply, chemical storage and disposal costs.

In addition, WEARMAX® seals from edge to edge, providing increased slip resistance and proven high abrasion resistance.

PROCESSING

Traffik visited the customer, “a Premier League club,” on six separate occasions between April and July 2018 to prepare and seal sections of rubber flooring in one area of the hall to the customer’s specification.

A total area of approx. 950m2 was treated with the WEARMAX® Transparent System. To minimize disruption to the venue, all work was carried out in the early morning in the designated zones. Each installation was completed within 24 hours and included:

– Preparation and cleaning of the rubber floor to remove impurities and polish residues and sand the surface. This included the removal of chewing gum, tape and adhesive residue.

– Flushing and neutralization to ensure pH neutrality of the soil surface.

– Covering door thresholds and skirting boards

– Dusting by means of a microfiber mop and vacuuming

– Application of WEARMAX® Universal Primer

– Application of the WEARMAX® ceramic layer

– Application of WEARMAX® Top Coat

Once WEARMAX® was applied and fully cured, pendulum tests were performed to ensure that the new flooring fully complied with British standards. In addition to our own certified testing, the floor was also subjected to independent testing.

RESULT

WEARMAX® Transparent has equipped the surface of the rubber floor with a transparent top layer. The new surface is very abrasion resistant and easy to clean. The surface does not require repolishing, buffing, stripping or sealing and can be cleaned quickly and effectively with water.

The overall result is a revitalized floor with increased durability.

Traffik is very proud of the collaboration with LSS, which resulted in a successful end result for the customer:

“LSS commissioned Traffik to conduct a survey of a Premier League club’s indoor arena to determine the wear and tear on the rubber floor, caused primarily by heavy foot traffic. At Traffik’s recommendation, WEARMAX® ceramics were applied in a hall area to preserve and protect the existing floor.”

“Traffik always worked professionally and was eager to get the project done quickly and efficiently.

After 18 months, the floor still looks “like new.””

“The surface has a smooth texture and has proven to be much more durable, withstanding the pressure of heavy foot traffic. Black marks have been visibly reduced, and the overall effect is a floor that looks great and is much easier for our cleaning crews to maintain.”

JMS (Contract Manager – LSS)

CALCULATE THE EXPENSES FOR YOUR CONSTRUCTION SITE

with our cost calculator

Based on our best practice projects, we have developed a simple cost calculator. You can use the calculator to get an overview of all the costs you may incur on your own project.

Since each construction site has different requirements, this calculator is for guidance only. We cannot guarantee that your actual cost will always be the approximate result.